Ever wondered how manufacturers get those super smooth finishes on 3D printed parts? Or how they turn raw prints into pro-grade products? The answer is vapor smoothing.

This advanced post-processing technique not only removes visible layer lines but also improves mechanical properties and durability. From consumer goods to medical devices, vapor smoothing is the new standard in manufacturing, bridging the gap between prototype and production ready.

In this article, we’ll look at vapor smoothing in manufacturing today, its benefits, industries, and future innovations.

What is Vapor Smoothing?

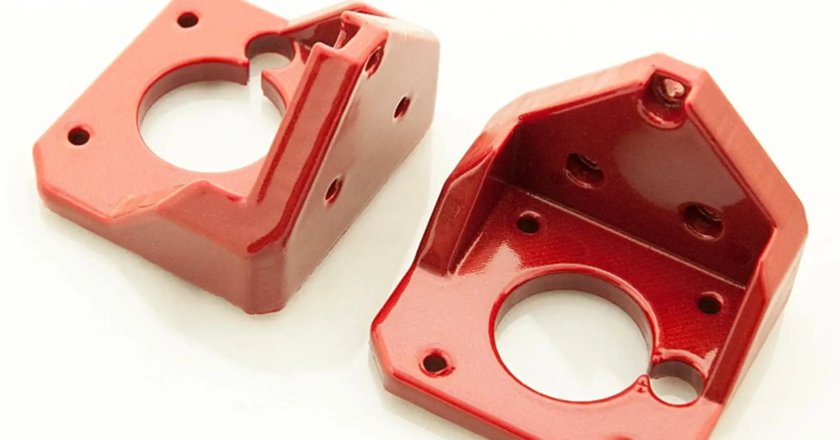

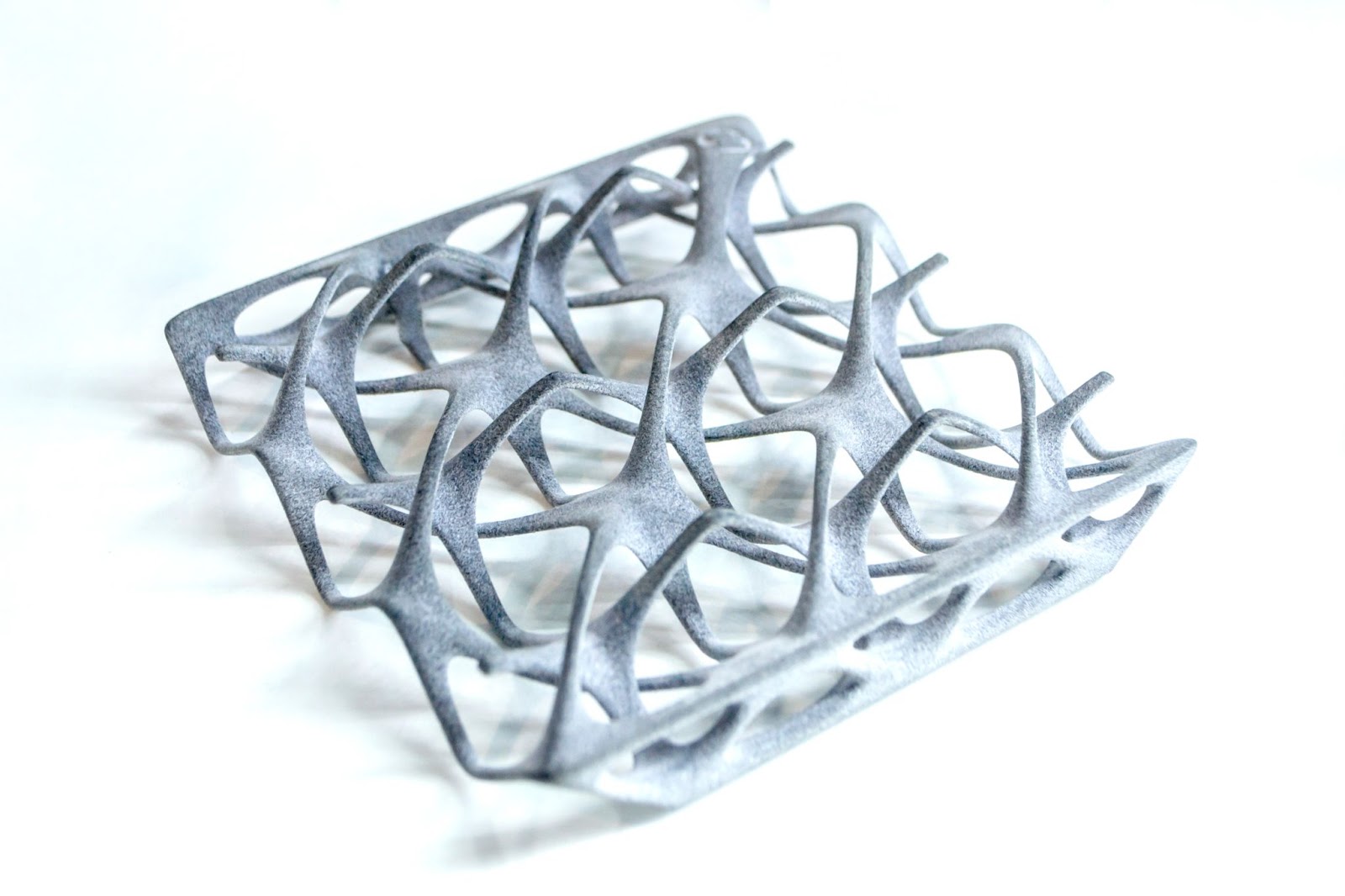

Vapor smoothing is a post-processing technique that improves the surface finish of 3D printed parts. It works by exposing the part to a chemical vapor that softens and smooths the outer layer, removes visible layer lines, and gives a polished look. This process improves both the looks and durability of the part, making it perfect for consumer-grade products and functional prototypes.

Benefits of Vapor Smoothing in Manufacturing

Vapor smoothing is turning 3D printed parts into high-quality, durable components, here’s the benefits of production

Surface Finish

Vapor smoothing removes visible layer lines by chemically softening the outer surface of the part. This allows the material to flow into gaps and irregularities and gives a uniform finish. The process gives near injection molded quality, which is required for products with tight tolerances or precise finishes, such as medical equipment or aerospace components. Vapor smoothing reduces surface roughness by 5-20 microns Ra to as low as 0.4-0.8 microns Ra.

Mechanical Properties

Surface imperfections are stress concentrators that weaken the part under load. By removing these imperfections, vapor smoothing increases the tensile strength and impact resistance of the material. 3D printed components are more robust for real-world applications, structural prototypes, and functional parts that are exposed to wear and tear. We at Dainsta aim to enhance the mechanical properties of your custom parts so that it performs well in high-performance applications.

Aesthetic Appeal

The process gives a polished look that rivals traditional manufacturing. This is especially valuable for consumer-grade products, like electronics, automotive interiors or luxury goods where aesthetics plays a big role in marketability. The glossy smooth finish achieved through vapor smoothing adds value to the product.

Post Processing

Traditional finishing methods like sanding or painting can be laborious, inconsistent and time consuming. Vapor smoothing simplifies this process and often eliminates the need for additional finishing. This streamlining not only reduces cost but also ensures consistency across multiple parts, which is key to scalability in additive manufacturing.

Materials Suitable for Vapor Smoothing and What It Can Do

| Material | What Vapor Smoothing Can Do |

| ABS Vapor Smoothing | Removes layer lines, improves strength and gives glossy finish. |

| PLA Vapor Smoothing | Removes surface roughness, gives smooth finish. |

| PETG Vapor Smoothing | Smooths surface while maintaining strength and flexibility. |

| ASA Vapor Smoothing | Smooths surface and UV resistance, perfect for outdoor use. |

| Polycarbonate (PC) Vapor Smoothing | Removes imperfections and gives polished finish. |

Vapor Smoothing Challenges and Limitations

While vapor Smoothing has many benefits, there are a few challenges and limitations to consider. These are material compatibility, health and safety, and environmental impact. Here’s a closer look at each:

Material Compatibility Issues

Not all 3D printing materials are suitable for vapor Smoothing. It works best with certain plastics like ABS and PLA which are more responsive to the chemical vapors. Other materials like nylons or flexible filaments may not get as smooth or could degrade during the process. This limits the versatility of vapor Smoothing as manufacturers need to carefully select materials that can withstand the chemical treatment without compromising their properties.

Health and Safety

Vapor Smoothing involves chemical solvents which can be hazardous. Prolonged exposure to these substances like styrene for ABS parts can be harmful if proper ventilation and protective equipment is not used. Workers handling these materials need to follow strict safety protocols to minimize the risk of inhalation, skin contact or other forms of exposure. So businesses need to invest in safety equipment and training to ensure safe working conditions.

Environmental Impact and Room for Innovation in Greener Solutions

The chemicals used in vapor Smoothing also pose environmental concerns. These solvents are often volatile organic compounds (VOCs) which can contribute to air pollution if not handled or disposed properly. Many manufacturers are looking for ways to reduce the environmental impact of vapor Smoothing by developing greener solvents or finding ways to recycle the chemicals used in the process. Innovations in sustainable vapor Smoothing can address these issues and make the process more eco-friendly in the long run.

Applications of Vapor Smoothing

| Industry | Application | Justification |

| Automotive | Vehicle parts (e.g., interior components) | Smooth finish and durability, appearance and functionality. |

| Aerospace | Precision parts (e.g., turbine blades) | Reduces roughness for better aerodynamics, friction reduction and longer life. |

| Medical Devices | Surgical tools and implants | Smooth surface, sterile and stronger. |

| Consumer Goods | Electronics, accessories | Appearance and reduce additional finishing steps. |

Summary

Vapor Smoothing is a post-processing technique that transforms 3D printed parts. Surface finish, mechanical properties, and polished appearance are key across industries like automotive, aerospace, medical devices, and consumer goods.

While material compatibility and environmental impact are challenges, the benefits – reduced post-processing time, longer part life and appearance – make it a must-have in modern manufacturing. As technology improves, vapor smoothing will become even more efficient and eco-friendly, solidifying its place in the future of manufacturing.

Looking for the best 3D printing services?

Let Dainsta help you get started.

Get in touch with us today!