You chose vacuum casting for your project because it offers incredible precision and a smooth finish, which is perfect for the detailed components, right? However, despite its many advantages, vacuum casting does come with its own set of challenges.

From dealing with air bubbles and maintaining dimensional accuracy to managing costs and ensuring a flawless surface, there are several hurdles that can arise.

But is there anything you could do about it? Absolutely yes.

In this article, we’ll discuss some common issues and explore effective solutions to ensure you get the best results from your vacuum casting process.

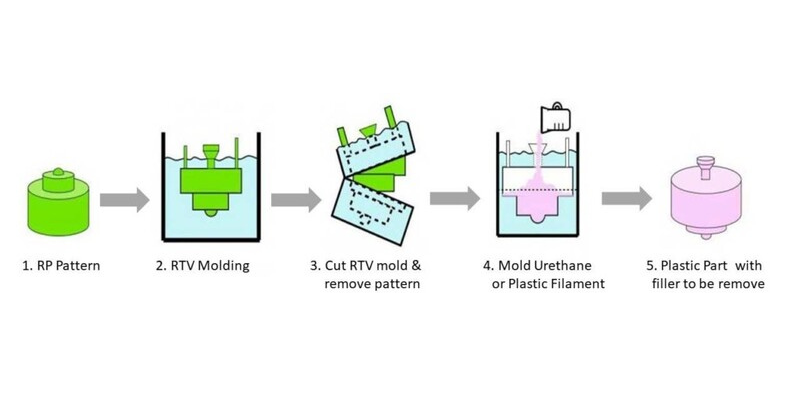

What is Vacuum Casting?

Vacuum casting is an advanced and cost-effective manufacturing technique used for creating prototypes and small production runs. It involves a two-part process with polyurethane and silicone molds, where a vacuum is applied to remove air bubbles and ensure a smooth finish.

This method is ideal for producing complex geometries and is often used as a bridge between prototyping and full-scale production. The process begins with a high-quality master pattern, usually made through 3D printing, which must be meticulously crafted to avoid transferring flaws to the final product.

This method is ideal for producing complex geometries and is often used as a bridge between prototyping and full-scale production. The process begins with a high-quality master pattern, usually made through 3D printing, which must be meticulously crafted to avoid transferring flaws to the final product.

Air bubbles can form in the casting material, leading to defects and weakened parts. This happens when air or gas gets trapped during the casting process. Porosity, or small voids within the material, can compromise the structural integrity and aesthetic quality of the final product. Effective vacuuming is crucial to minimize these issues and ensure a dense, defect-free casting.

Dimensional Accuracy

Maintaining precise dimensions can be challenging with vacuum casting. Variations in mold temperature, material flow, or vacuum pressure can lead to slight inaccuracies in the final component. These discrepancies can affect the performance and fit of parts, making it essential to use high-quality molds and closely monitor process parameters to achieve accurate results.

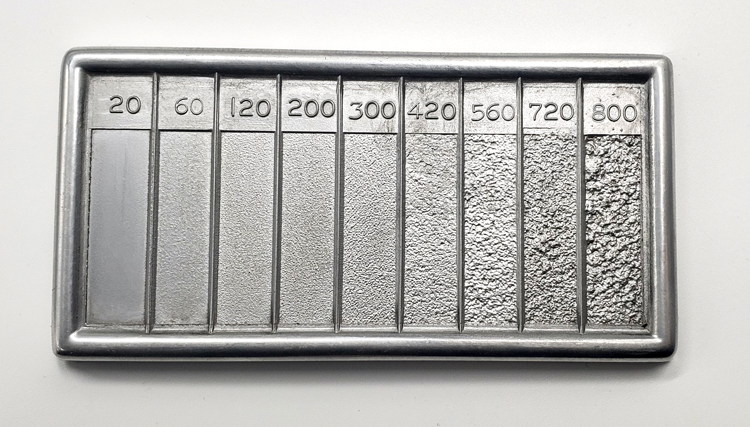

Surface Finish

Achieving a smooth surface finish can be difficult, especially for complex or intricate designs. Surface imperfections, such as texture inconsistencies or minor defects, can occur if the mold is not properly prepared or if the casting material doesn’t fill the mold evenly. Post-processing steps like sanding or coating may be required to improve the final appearance.

Material Limitations

Not all materials are suitable for vacuum casting. Some materials may not flow well or may not cure correctly under vacuum conditions, limiting the types of components that can be produced. It’s important to choose compatible materials and adjust the casting parameters to ensure that the material properties meet the desired performance standards.

Cost and Time Efficiency

While vacuum casting is cost-effective for small runs, the initial setup can be expensive, especially for high-quality molds. Additionally, the time required for mold preparation and curing can impact overall efficiency. Balancing these factors is crucial to maintaining cost-effectiveness and meeting project deadlines, particularly for time-sensitive or budget-constrained projects.

How to address these challenges?

In order to address these specific issues, you can do the following things:

Minimize air bubbles

To minimize air bubbles and porosity in vacuum casting, ensure that the mold is placed in a vacuum chamber before pouring the casting material. This removes trapped air and gas, which helps to prevent bubbles in the final product.

Additionally, using degassing equipment to pre-treat the casting material can further reduce the risk of bubbles. Consistent monitoring and maintenance of proper vacuum levels throughout the casting process will also contribute to a more defect-free result.

Maintaining dimensional accuracy

For maintaining dimensional accuracy, it’s crucial to ensure that molds are precisely manufactured and maintained to exact specifications. High-quality, stable mold materials should be used, and equipment must be regularly checked and calibrated to maintain consistent temperature and pressure.

Implementing rigorous quality control measures, such as using precise measurement tools and conducting regular inspections, will help verify that the dimensions of the cast components meet the required tolerances.

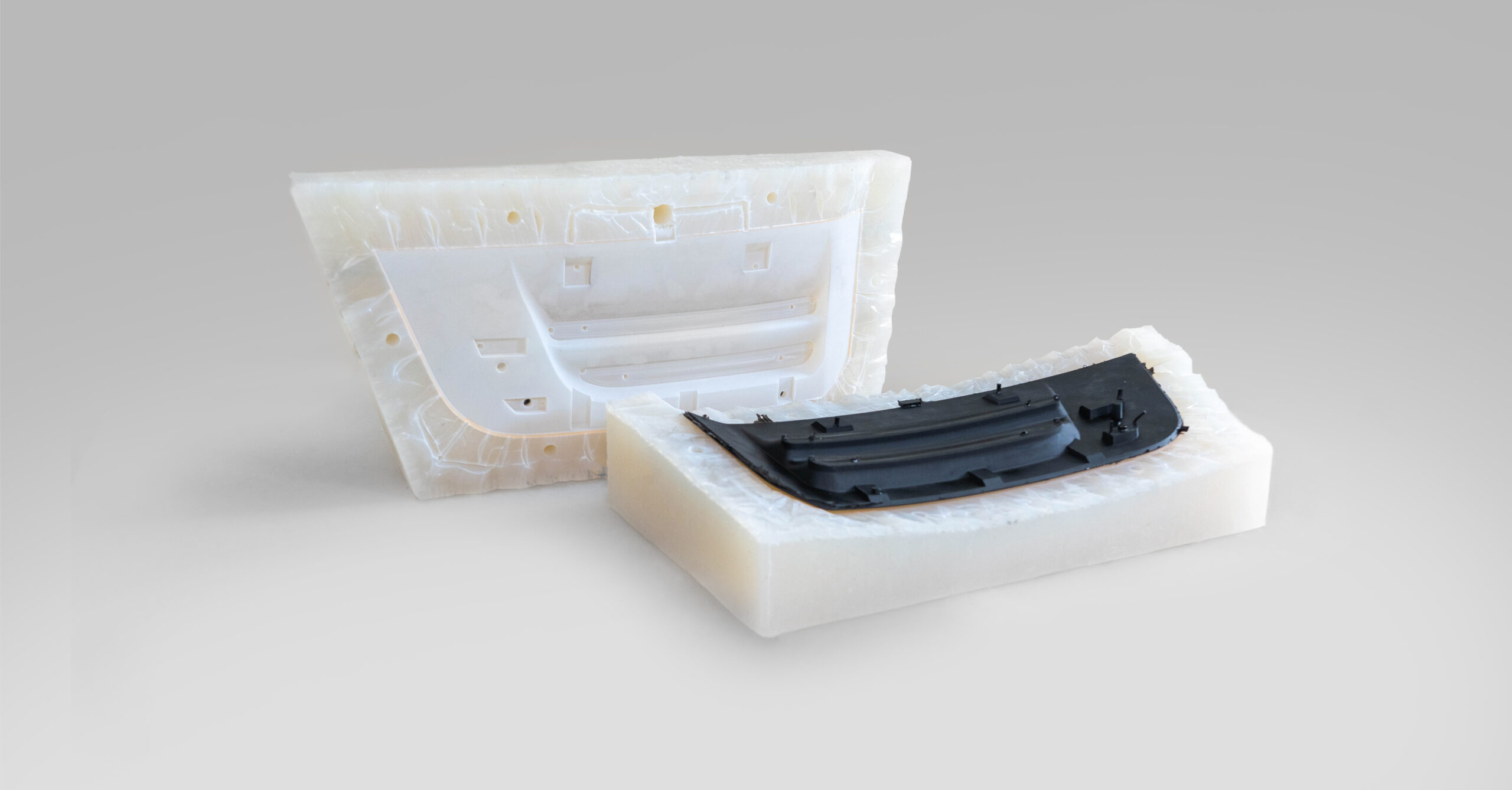

Achieving a smooth surface finish

Achieving a smooth surface finish involves properly preparing the mold to eliminate any imperfections before casting. Using high-quality silicone molds and ensuring they are clean and free from debris will also improve the final surface.

Post-processing techniques, such as sanding, polishing, or applying a surface coating, can address any minor defects or texture inconsistencies that occur during the casting process. Regular mold maintenance and cleaning further enhance the surface quality.

Selecting right materials

Material limitations can be addressed by selecting materials specifically designed for vacuum casting that have compatible flow and curing characteristics. Conduct thorough testing to ensure the chosen material performs well under vacuum conditions.

Consider using advanced materials that offer better performance and reliability, and work closely with material suppliers to address any compatibility issues and optimize material properties for your specific application.

Optimize the production process

To improve cost and time efficiency, optimize the production process by streamlining mold design and setup to reduce costs. Employ efficient mold-making techniques and consider using reusable molds when possible.

Implement effective project management strategies, such as careful planning and scheduling, to avoid delays and reduce overall production time. Leveraging advancements in technology and automation can also help enhance efficiency and lower production costs.

Conclusion

While vacuum casting offers numerous advantages for creating high-precision prototypes and small production runs, it also comes with its own set of challenges.

To navigate issues such as air bubbles, dimensional accuracy, surface finish, material limitations, and cost efficiency, it is recommended to approach experts in vacuum casting.

Companies like Dainsta specialize in ensuring high-quality results and can provide valuable insights and solutions tailored to your specific needs.

Their expertise can help you overcome common obstacles and achieve the best possible outcomes in your vacuum casting projects.

Looking for vacuum casting experts for high-performance parts?

Get in touch with Dainsta.