Aluminium, renowned for its lightweight yet sturdy nature, offers remarkable ease of machining, 3D printing, and metal fabrication process. Its natural corrosion resistance and excellent thermal and electrical conductivity make it versatile for outdoor, marine, and electronic applications. A CNC Aluminium machining process can further enhance its machinability, making it suitable for various mechanical applications.

Moreover, its cost-effectiveness makes it a top choice across diverse manufacturing needs, ensuring lower production costs.

There are hundreds of Aluminium alloys; however, several alloys exhibit unique mechanical properties suitable for various applications. Dainsta specialises in most Aluminium alloys and delivers customised solutions across multiple industries

Aluminium 6000 series is versatile and commonly used, featuring good mechanical properties and corrosion resistance, suitable for structural and architectural applications.

Aluminium 6060 is well-suited for extrusion and decorative anodizing. It offers moderate to high corrosion resistance. It is commonly used in architectural, automotive, and industrial applications.

Aluminium 6061 exhibits higher conductibility, corrosion resistance & excellent cold work properties. It's ideal for aerospace, automobile, and marine applications.

Aluminium 6063 is a versatile alloy with a higher degree of extrudability and weldability. It provides moderate corrosion resistance that surface treatments can enhance.

Aluminium 6082 offers excellent strength and toughness and is moderately corrosion-resistant. CNC machined Aluminium 6082 is a good choice for high-stress applications where strength and durability are important.

Aluminium 6082 can bear heavy loads. This alloy exhibits good weldability, enabling the fabrication of welded assemblies and structures easily.

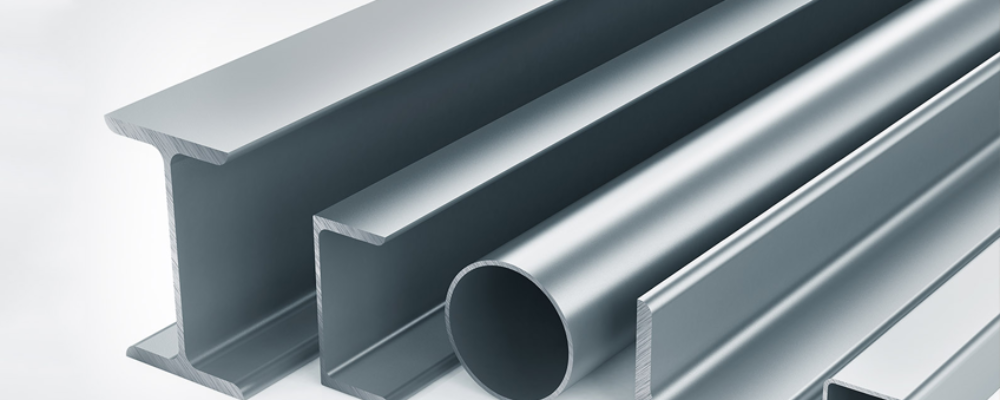

Aluminium 6061, or structural aluminium, is known for structural integrity and weldability.

It can be extruded, rolled, or forged into various shapes. It offers superior strength in the aerospace and construction industries.

Aluminium 7000 series comprises alloys with additional elements like lithium for improved strength and lightweight properties, used in aerospace.

Aluminium 7075 is valued for its high fatigue resistance. It has high strength and excellent machinability, making it a good choice for aerospace and defence equipment.

Aluminium 7075 is valued for its high fatigue resistance. It has high strength and excellent machinability, making it a good choice for aerospace and defence equipment.

Aluminium 7075-T6 offers exceptional strength and good fatigue resistance, which can withstand repeated stress cycles without failure.

Aluminium 7075 is valued for its high fatigue resistance. It has high strength and excellent machinability, making it a good choice for aerospace and defence equipment.

Copper is the main alloying element in the Aluminium 2000 series. It provides high strength and excellent machinability, common in aerospace structures

Aluminium 2024 exhibits excellent fatigue resistance. Its impressive strength and relatively low weight make it suitable for applications like aircraft components.

Aluminium 2017 is highly ductile with moderate to high better load-bearing capacity. Its mechanical properties can be enhanced with heat treatments.

Aluminium 2014 is known for superior machinability. Though it offers limited strength, it can be easily tailored to meet specific application requirements.

Known for excellent corrosion resistance and weldability, Aluminium 5000 series is often used in marine and high performance applications.

Al 5052 offers exceptional water resistance and decent strength, making it suitable for structural applications.

Aluminium 5083 is a tough and weldable alloy capable of withstanding seawater and industrial chemical environments.

We offer a range of Aluminium 8000 grades, including Grade 8006 (1.5% Fe, 0.5% Mn), ideal for demanding applications such as packaging and complex formed products.

Aluminium MIC6 exhibits high thermal conductivity, and MIC6 offers excellent machinability. It is commonly used in applications where heat dissipation is an important part.

We use Grade 8006 (1.5% Fe, 0.5% Mn) aluminium alloy for its exceptional strength, high ductility, and superior formability, making it ideal for packaging applications and complex formed products.