In medical devices, challenges such as friction-induced tissue damage, infection risks from microbial adherence, and blood clot formation due to bodily fluids pose significant risks to patients.

To address these critical issues, the introduction of PTFE (polytetrafluoroethylene) coatings has emerged as a crucial solution. In fact, these coatings are widely used for many Medical devices and equipment in the industry.

In this article, we are going to discuss PTFE coatings in Medical applications in detail.

Let’s get started!

What is PTFE Coating?

PTFE coating is a thin layer of Polytetrafluoroethylene applied to surfaces like metals or plastics. It provides non-stick properties and chemical resistance and can withstand high temperatures. Apart from medical devices, this coating process improves surface performance in industries like automotive, aerospace, and cookware as well.

You may wonder, is PTFE Coatings safe, right?

The answer is Yes. Understand that PTFE coating is generally considered safe for its intended applications. When properly applied and cured, PTFE forms a stable and inert layer that does not react with chemicals or release harmful substances.

Properties of PTFE Coating

So, if we are clear that PTFE-coated medical devices have an edge in terms of performance and longevity, let’s talk about what properties make PTFE an ideal coating choice:

Chemical Resistance

PTFE (polytetrafluoroethylene) is highly resistant to a wide array of chemicals, making it ideal for medical environments where exposure to harsh substances is common. This resistance ensures that PTFE-coated devices remain stable and effective, even in aggressive chemical environments.

Low Friction

One of the standout properties of PTFE is its exceptionally low coefficient of friction. This feature reduces wear and tear, enhancing the durability and performance of medical devices such as catheters and guidewires.

Biocompatibility

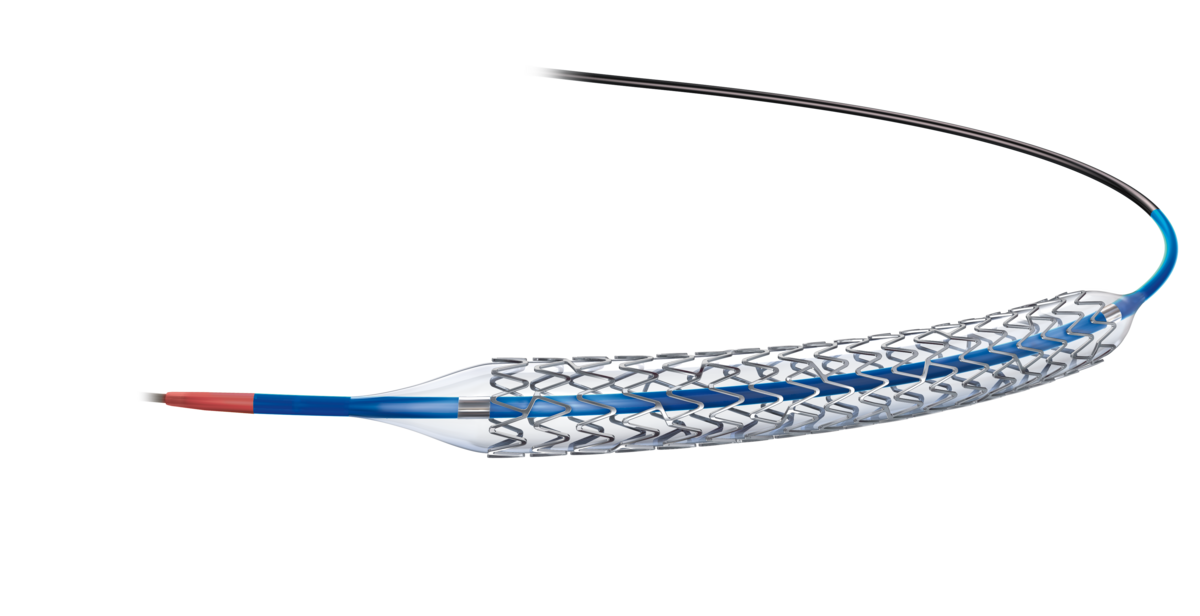

PTFE is biocompatible, meaning it is safe for use in contact with human tissue and bodily fluids. This property is crucial for implantable devices and other medical applications where long-term compatibility is required. PTFE-Coated Stents can be a good example of this.

Thermal Stability

PTFE coating maintains its properties over a wide temperature range, making it suitable for applications involving extreme temperatures, whether in sterilization processes or high-temperature diagnostic equipment.

Applications in Medical Devices

Here are some medical devices where using PTFE coatings is beneficial; let’s talk about all of them one by one:

Catheters and Guidewires

PTFE-coated catheters and guidewires benefit from reduced friction, facilitating smoother insertion and navigation through blood vessels. The smooth surface prevents biological material buildup, maintains functionality, and reduces infection risks.

Surgical Instruments

The non-stick properties of PTFE-coated surgical instruments make them easier to clean and sterilize, reducing infection risk and extending lifespan. Biological materials do not adhere to the surface, increasing cost savings for healthcare facilities.

Implantable Devices

Coatings on devices, like joint replacements and vascular grafts, ensure durability, reducing rejection and inflammation. This maintains structural integrity and functionality over time, enhancing patient safety and device efficacy.

Medical Implants

PTFE is used in various implants due to its biocompatibility and ability to integrate well with human tissue. Its inert nature minimizes adverse reactions, ensuring stability and effectiveness over long periods. This makes PTFE-coated implants reliable and safe, contributing to better patient outcomes and long-term functionality.

Applications in Medical Equipment

On the other hand, PTFE coatings can also be used in some medical equipment, which are as follows:

Diagnostic Equipment

PTFE coatings in diagnostic equipment components improve reliability and longevity by providing a protective barrier against reactive substances. This ensures consistent and accurate performance, which is crucial for diagnostic accuracy.

By preventing corrosion and degradation, PTFE maintains the integrity of the equipment, reducing maintenance costs and downtime and ultimately supporting efficient and precise diagnostic processes in medical settings.

It is worth understanding that In the case of PTFE, ensuring proper adhesion of PTFE coatings to substrate materials can be challenging due to its non-stick properties.

And a couple of problems like costs and uniformity may arise too. Hence, it is always advised to pick a reliable partner for PTFE coating services.

Laboratory Tools

In laboratory environments, PTFE-coated tools resist harsh chemicals, ensuring durability and safety. This chemical resistance prevents degradation and extends the life of the tools, making them ideal for frequent exposure to aggressive substances.

Additionally, PTFE’s non-stick properties facilitate easier cleaning, reducing contamination risks and maintaining high standards of laboratory hygiene and functionality.

Fluid Handling Systems

Fluid handling systems benefit from PTFE’s non-reactive and easy-to-clean properties, which are essential for maintaining sterility and minimizing contamination. This is particularly important in transporting medical fluids like blood and medications.

PTFE coatings ensure that these systems remain uncontaminated and efficient in medical fluid management.

PTFE Coatings vs Teflon Coating

When comparing PTFE coatings versus Teflon coatings, it’s important to understand that they are essentially the same material. PTFE (Polytetrafluoroethylene) is the chemical name for the polymer, while Teflon is a brand name owned by Chemours, formerly DuPont, under which PTFE is marketed.

Therefore, there is no technical difference between PTFE coatings and Teflon coatings in terms of chemical composition or basic properties.

Both PTFE and Teflon coatings offer outstanding non-stick properties, excellent chemical resistance, and high thermal stability, making them suitable for a wide range of applications, including cookware, industrial equipment, and medical devices.

The choice between PTFE and Teflon coatings typically comes down to brand preference, availability, and specific application requirements rather than any inherent differences in performance.

Conclusion

Looking ahead, advancements in PTFE continue to expand possibilities in medical devices. Innovations may focus on further improving biocompatibility, enhancing durability under extreme conditions, or adapting coatings for new medical challenges.

Moreover, ongoing research aims to optimize coating processes to meet increasingly stringent regulatory standards and evolving medical demands.

As medical technology evolves, PTFE and Teflon coatings are poised to play an essential part in advancing diagnostic accuracy, patient care, and the overall efficiency of medical procedures.

Looking for reliable partners for PTFE Coating services?

Let Dainsta get you started.