FDA Compliant Polymer Coating

What is FDA Compliant Polymer Coating

FDA-compliant polymer coatings for metals are designed to meet the regulations and guidelines set forth by the U.S. Food and Drug Administration (FDA) for materials that come into contact with food or pharmaceutical products. These coatings are specifically formulated to ensure safety and non-toxicity when used in applications where direct contact with consumables is possible.

Our Polymer Coating Process

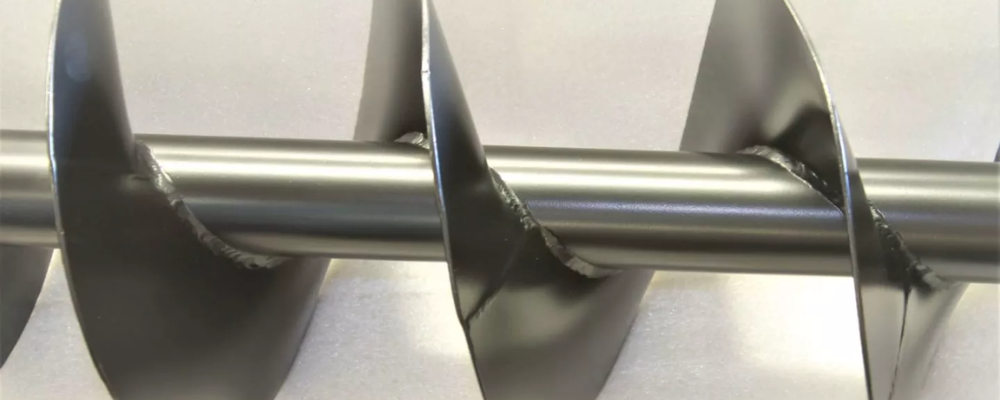

Applying an FDA-compliant polymer coating to metal involves thorough surface preparation and optional primer application for enhanced adhesion, followed by uniform coating application using methods like spraying or dipping.

After coating, curing or drying processes are employed to achieve desired properties, with subsequent quality control checks ensuring compliance with FDA regulations. Documentation certifying FDA compliance is provided, emphasising adherence to safety protocols and expert consultation to guarantee suitability for food or pharmaceutical applications. After this, the metal possesses features such as:

They are formulated to be non-toxic, ensuring that no harmful substances are transferred to consumables.

These coatings resist corrosion and degradation from acidic or alkaline substances commonly found in food or pharmaceutical processing.

They provide a protective barrier that enhances the longevity of metal components, reducing the need for frequent replacements.

Dainsta’s FDA compliant polymer coatings for metal offer a host of benefits tailored to the food and pharmaceutical industries. These coatings ensure product safety and regulatory compliance, guarding against contamination risks. Their non-toxic formulation and chemical resistance maintain product integrity while promoting hygiene and durability, ultimately supporting Dainsta’s commitment to quality and consumer well-being.